Modelling Phase Transformations in Steel Alloys

Mathias Mul

(COSSE student, double degree with

TU Berlin)

Supervisor: Fred Vermolen

Site of the project:

Tata Steel

Breedbandweg 1

1951 MC Velsen-Noord

Supervisor Tata Steel: Kees Bos

start of the project: November 2013

In May 2014 the

Interim Thesis

has appeared

and a

presentation

has been given.

The Master project has been finished in September 2014

by the completion of the

Masters Thesis

and a final presentation

has been given.

For working address etc. we refer to our

alumnipage.

Summary of the master project:

The mechanical properties of steel are determined by its composition and

microstructure. There are many ways to adapt the microstructure of steel

alloys. Thermal treatment is widely used to give steel its properties

for specific purposes. Effects on the internal structure of a steel

alloy under cooling or heating can be modelled on micro scale. The

average grain size is the most interesting microstructure parameter,

because it has been extensively correlated to mechanical properties.

An explanation for the different behaviour lies within the

transformation of the iron lattice from face centred cubic (fcc) at

higher temperatures to body centred cubic (bcc) at lower temperatures.

The high temperature phase is referred to as austenite and the low

temperature phase is referred to as ferrite. Therefore, the phase change

from fcc to bcc is also called austenite-ferrite transformation. (image

below)

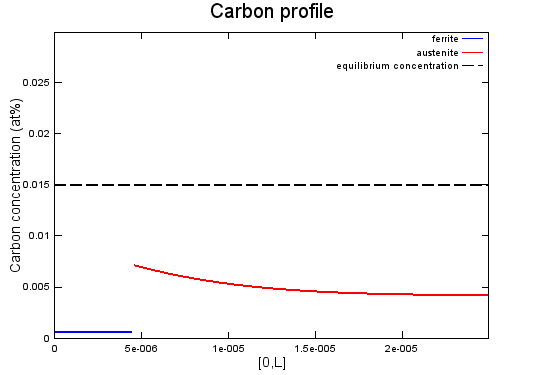

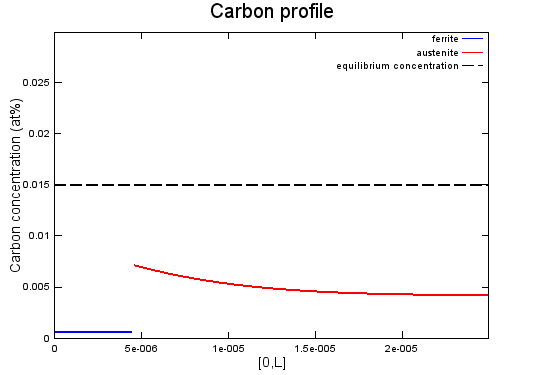

Steel consists mainly of the elements iron (Fe) and carbon (C). The

movement of the interface between austenite and ferrite depends partly

on the carbon concentration at the interface. Ferrite is saturated with

carbon at much lower concentrations than austenite. Therefore, during

the transformation, carbon is pushed ahead of the moving interface. This

can be modelled by the diffusion equation, which mathematically

describes carbon spreading through the austenite. (image below)

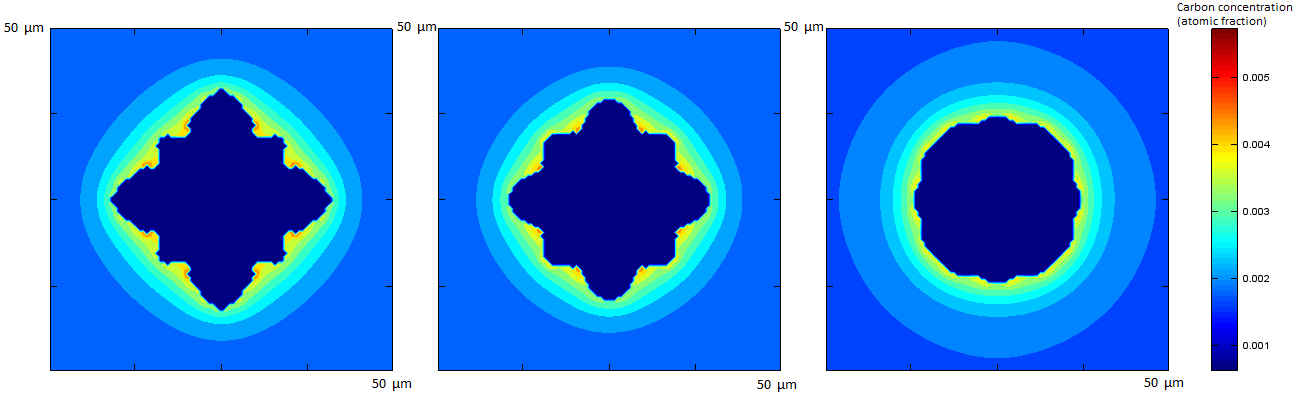

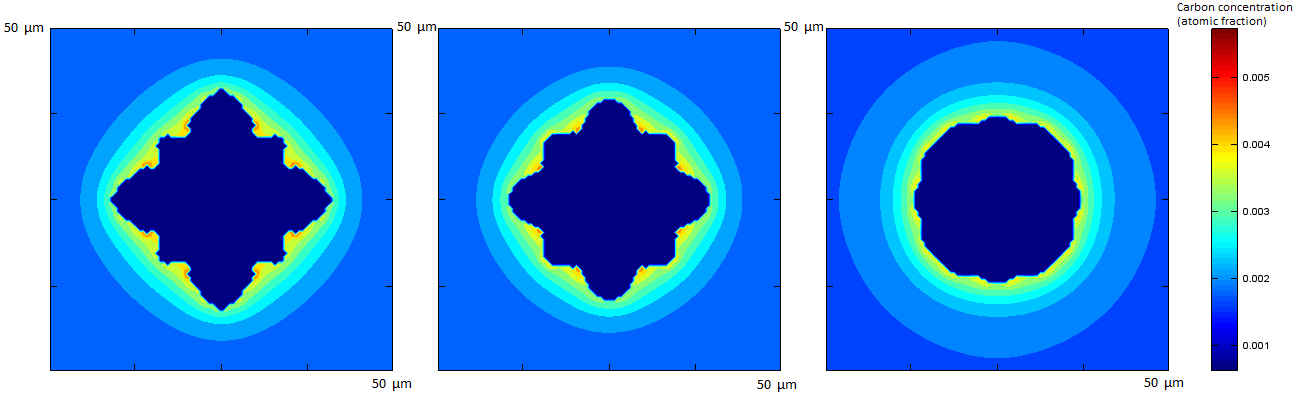

The goal of this thesis is to model grain growth of different phases in

an accurate and efficient way. This can be done using Cellular Automata

(CA) models. A CA model is a discrete model with a regular grid of

cells. Each cell has a set of properties, most importantly its state,

neighbourhood, and transformation rule. Given an initial state, each

time step the state of a cell is updated by a rule that usually is a

mathematical function of the states of its neighbours.

Results of simulations to estimate the stability of the interface.

Contact information:

Kees

Vuik

Back to the

home page

or the

Master students page of Kees Vuik

![]()

![]()